Condition Monitoring & Thermal Imaging

Machines don't last forever! The problem isn’t that it will eventually fail, but the consequences of it failing unexpectedly. In fact, a machine is more likely to fail just when you need it most; when it's running for longer periods than usual or working that bit harder.

If you can predict the failure of a machine early enough, you have an opportunity to do something about it to minimise downtime and disruption to production. Often a simple remedial action, such as re-greasing, bearing adjustment or bearing change at the right time can prevent not only failure, but also any permanent damage or loss of production.

Unfortunately, neither past experience, nor downtime between failures, can predict the failure of any particular machine. Some machines will fail much earlier and some much later than expected. The only approach to achieving such machine specific details is to utilise Condition Monitoring.

At Peel Bearings Tools & Filters, we can offer you a Condition Monitoring (CM) service so you can implement a Condition Based Maintenance (CBM) program. The advantage to CBM is that it's scheduled when you have all the necessary components, having had time to order them. This means the process can be carried out at a time when it will cause the least disruption to your production.

We can tailor a condition monitoring program to suit your requirements that can be adjusted when the need arises. Our staff use the very latest in technology to monitor and report the condition of your machines.

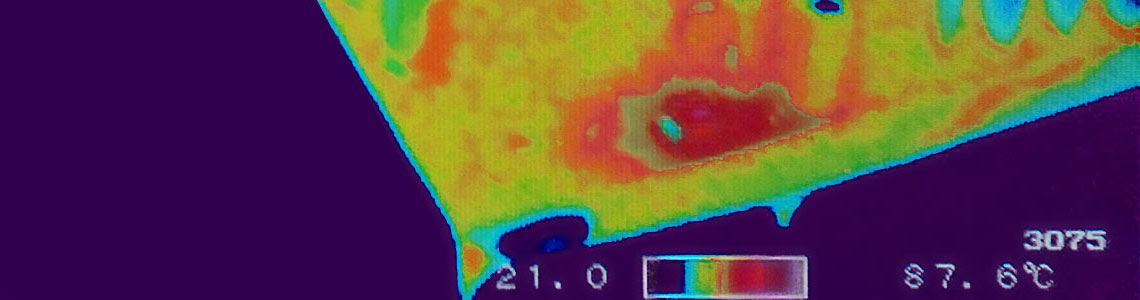

We also offer Thermal Imaging of your switch boards. This process indicates when your wiring and switches are starting to overheat. We're able to detect problems when your plant is running at capacity so that you can track down the problem before it becomes disastrous.

These services can save you lots of downtime, stress and money for the future.

Contact us to organise a free site visit and quote.

Servicing Rockingham, Mandurah & Pinjarra WA.